Design process

The team used a design process synthesized from their own experience and the structure of the ME421 Curriculum at Duke university.

1. Clarify Problem and Identify User Needs 2. Functional Analysis 3. Design Concept 4.

2025 Senior Design Project Eli Page, Eric Ma, Cody Rosolowsky, Julian Camacho, Alexia Moringo

The objective of this project was to retrofit a Shopmaster El-Dorado manual mill and lathe machine with CNC hardware and provide educational resources to significantly lower the barrier of entry to CNC machining on Duke University's Campus.

The team used a design process synthesized from their own experience and the structure of the ME421 Curriculum at Duke university.

1. Clarify Problem and Identify User Needs 2. Functional Analysis 3. Design Concept 4.

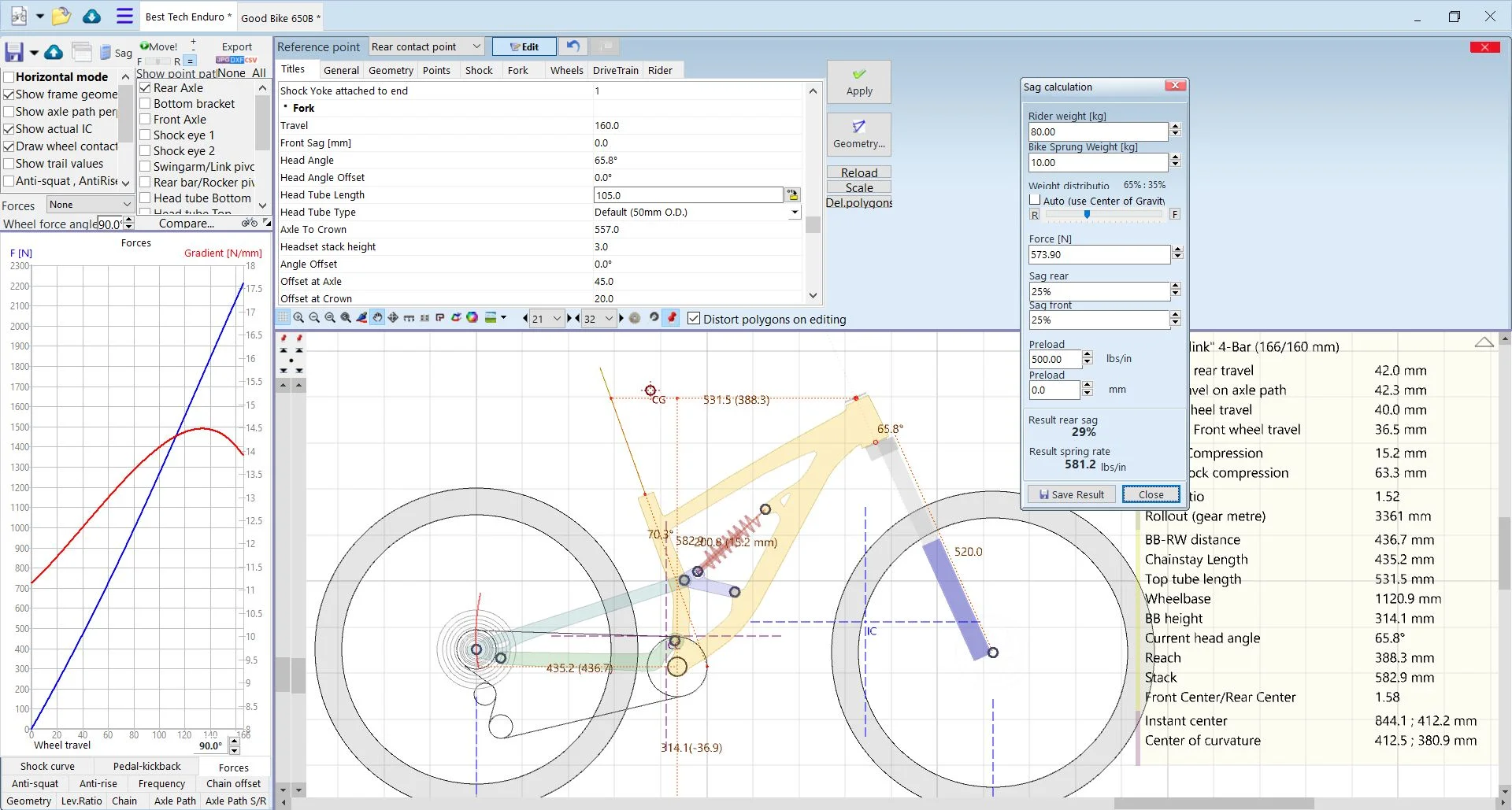

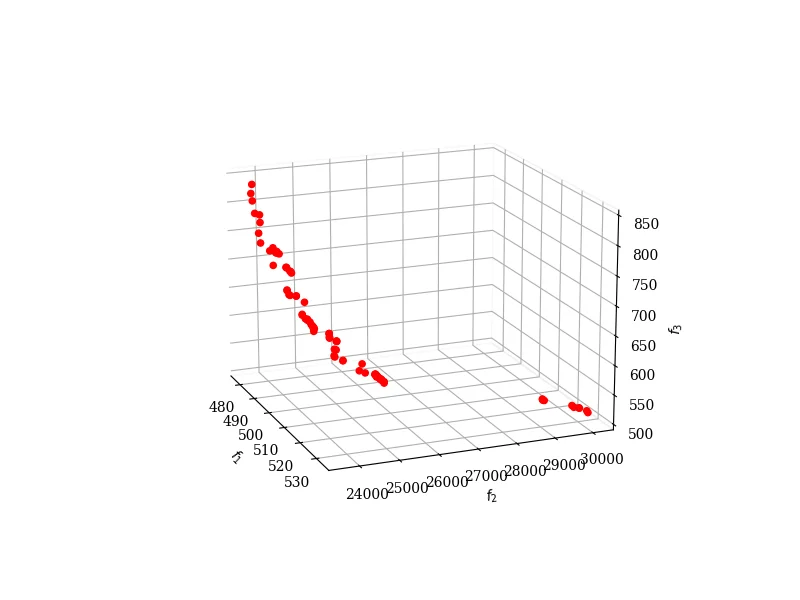

All of the information needed can be condensed into a few digestible graphs: Rear Axle Path, Leverage Ratio, and Anti-Rise.

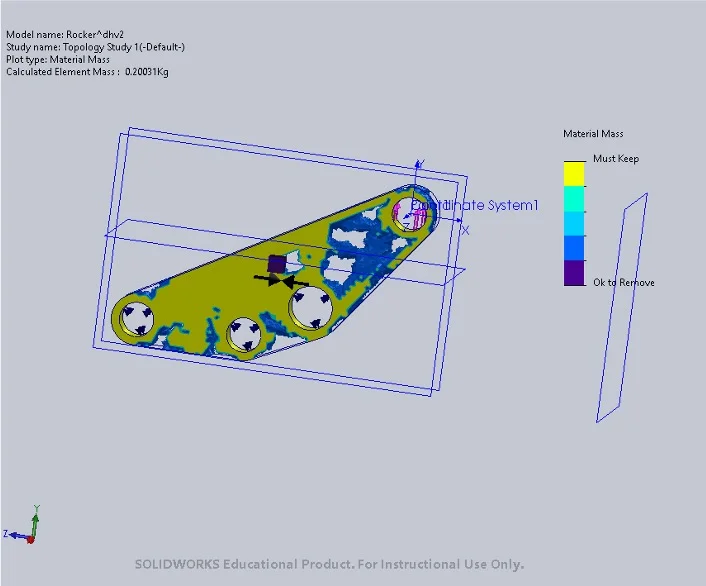

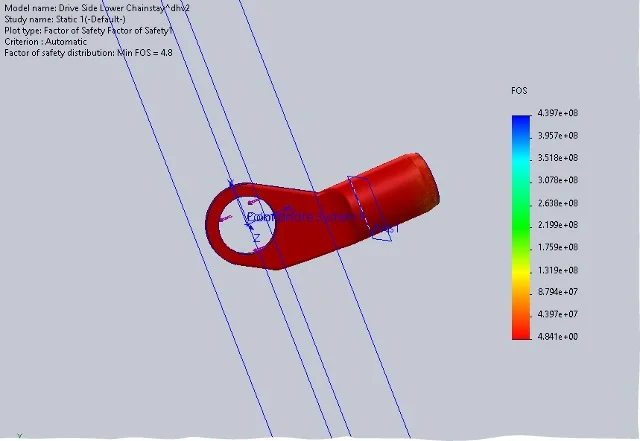

After developiing a the user needs and distilling them into design requirements, the team set out rapidly designing and fixing parts of the machine. The team split into an electronics and mechanical team to speed up the development process.

This stage involved designing and building an adjustable jig, machining components, and assembling the bike frame. The focus was on creating a precise and efficient fabrication process.

In the final stage, a testing harness will be designed complete with with accelerometers, strain gauges, and biometric sensors to analyze the performance of the human-machine system.